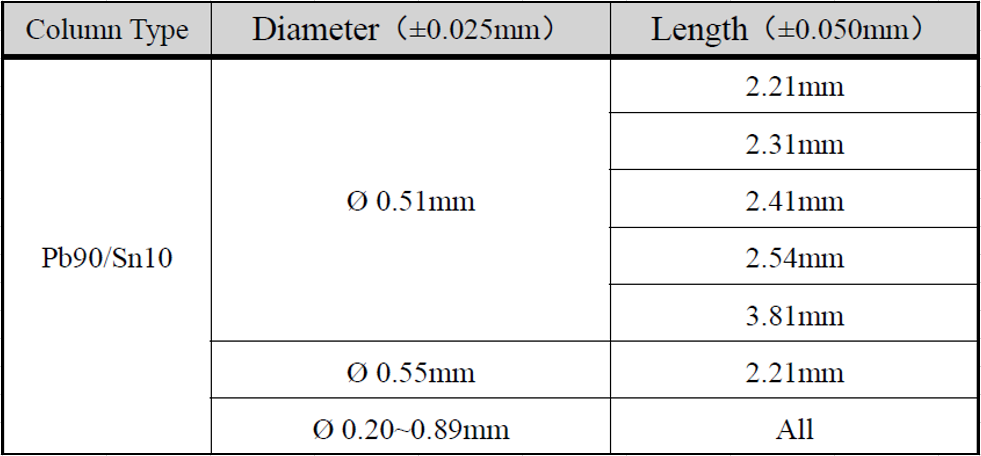

Solder Column

Plain solder wire is commonly produced by high lead alloy,like Sn10 / Pb90 alloy.The solidus temperature of the Sn10 / Pb90 alloy is 275 ℃, the liquidus temperature 302 ℃.The length and diameter size can be choose according to actual production requirements,but 0.51 mm in diameter and 2.21 mm in length is

recommended. Sn63 / Pb37 eutectic alloy is recommended to weld.

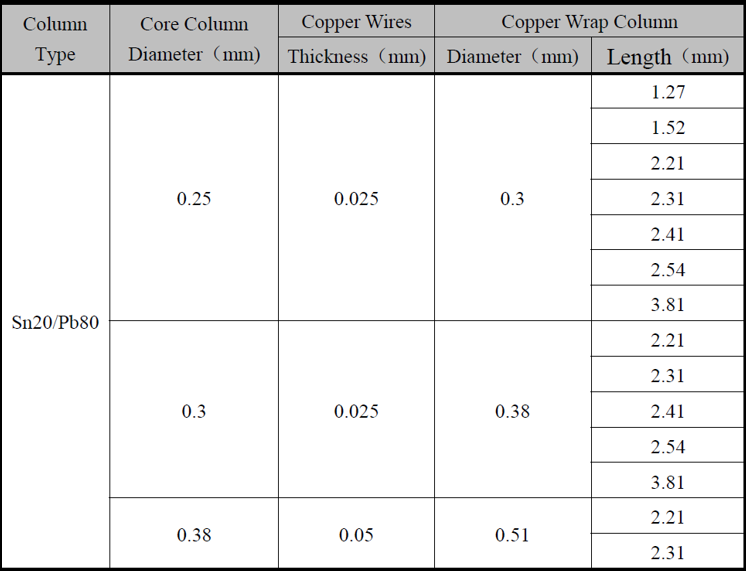

Copper Wrap Column

Copper wrap column is produced by high lead tin alloy like Sn20 / Pb80 alloy as the main welding column. And on the main column surface,we wind a certain thickness and spacing of the copper wires or copper foils, then a layer of Sn63 / Pb37 eutectic alloy is hot solder coating.0.51 mm in diameter and 2.21 mm in length is recommended. Sn63 / Pb37 eutectic alloy is recommended to weld.Compared with traditional plain solder wire,copper wrap column has better thermal cycling

ability, and Sn20 / Pb80 alloy (The solidus temperature, 183 ℃, the liquidus temperature, 280 ℃) makes it more suitable for reflow soldering process window.

The welding column also can be produced by Sn10 / Pb90 alloy,which has a more wide process window than Sn20 / Pb80 in the second PCB packaging .